- Sand Control Pipes

- Casing & Tubing

- API Stabilizer

- DP & Hwdp& Drill Collar

- Top Drive Syetem

- Drill Rig Spare Parts

- Add:binhai new district, tianjin city, china

- Tel:0086-22-25927368

- Fax:0086-22-25927369

- E-mail:471656480@qq.com

- Contacts:Linda

API sand control screen pipes

The global leader of sand control screen pipes for a wide range series and purposes

BPE is always dedicated to be the leader of sand control screen pipes, and produce all kinds of sand control screen pipes for more than 300000 meters every year. we have:

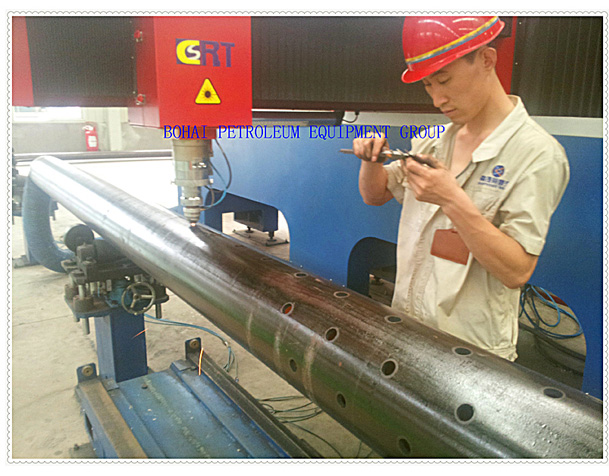

-- 50 sets high precision Laser CNC cutting machines in 2012,

-- wire-wrapped screen assembling line , including 38 sets station professional machines, precision CNC wire-wrapped machines of ± 0.02mm, straight seam welding machines, spiral welding machines, spot welding machines, the total annual output is about 80000m;

Their outstanding advantages:

﹡wider processing range:

Maximum cutting thickness: carbon steel 25mm, stainless steel 16mm; sheet processing specifications: 1500mm-6000mm; for processing complex graphics and multi-channel processing component parts be a molding.

﹡higher processing precision

High quality slot: Minimum width 0.1mm, high accuracy: typically hole center distance error 0.1-0.2 mm; repeat accuracy: ± 0.01mm; Cut surface finish: 6.3

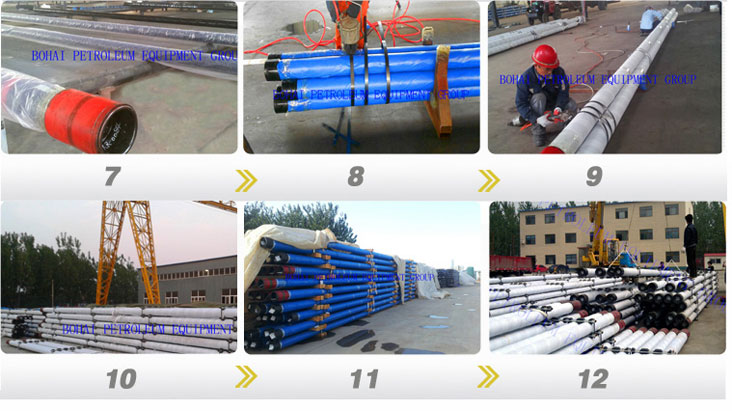

At the same time, we pay more attention to delicacy management and strictly control every step of slotted liner production.

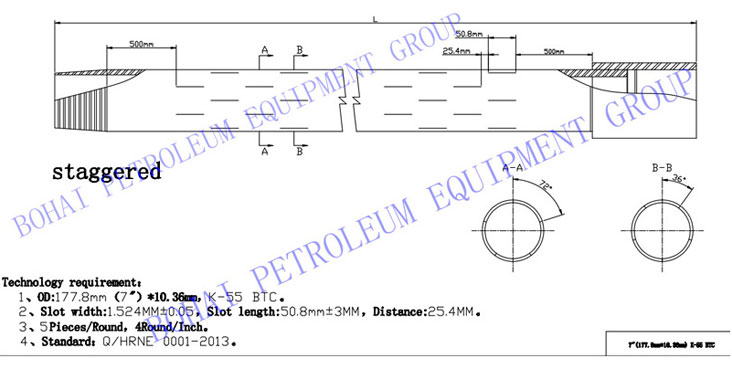

------ Professional slotted liner drawing design

Our professional design team with oil & gas industry experts, senior engineers would conduct the layer, graph, dynamic simulation, mechanical analysis and also design the slotted liner / perforated / wire wrap type, material, slots structure, slot distribution pattern and geometric parameters, finally give the drawings according to customers’ detailed inquiry and provide it to customers for checking. If there are some places to be modified, our designers will discuss if it is correct or not.

------ Strict process inspection

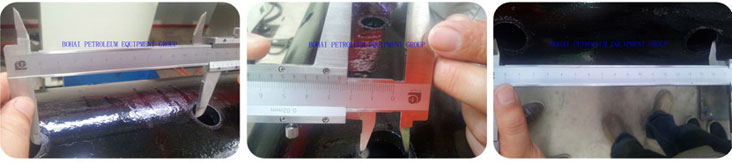

Our engineers write the laser CNC programs according to the processing to assure the superior quality. During the processing, the workers measure the slots or holes size every 2 meters to avoid the deviation.

It is the important part that our quality department conducts the selective inspection.

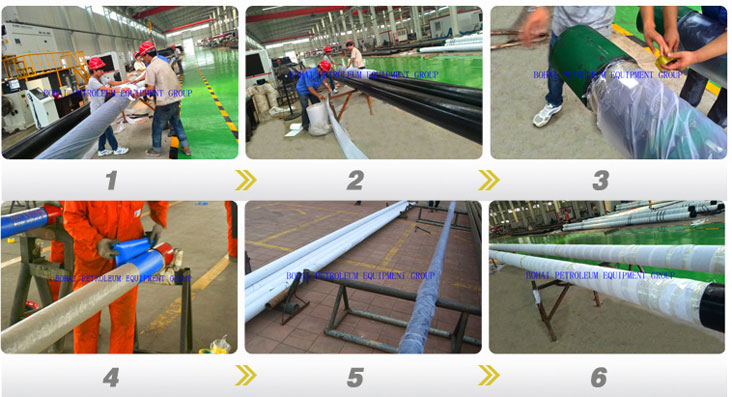

------ Thoroughly deburring and clean

When slotting or perforating, there are burrs on the casing pipes’ surface or dross adhesions around the slots or holes, which must be cleaned and deburred thoroughly from the exterior and interior. After this, some damaged surfaces must be repainted.

------ Retighen the casing/ tubing coupling

First, brash the high temperature and pressure thread sealing grease;

Second, retighten the couplings and thread protectors according to API 5CT standard.

After checking all the information of every slotted liners or perforated pipes and make all the information is correct, we will go on the next package step. First pack the pipes with stretch film and plastic film, and then wrap the adhesive tape, finally tie several pipes in a bundle with Steel packing belt or support / stand.

------ High- efficient and safe transportation

In order to avoid to damaging the casing (tubing) threads, we usually lift them with slings.