- Sand Control Pipes

- Casing & Tubing

- API Stabilizer

- DP & Hwdp& Drill Collar

- Top Drive Syetem

- Drill Rig Spare Parts

- Add:binhai new district, tianjin city, china

- Tel:0086-22-25927368

- Fax:0086-22-25927369

- E-mail:471656480@qq.com

- Contacts:Linda

Tool joint

Tool joint, as an important component of drill pipe, is made from AISI 4137H alloy steel materials complying with API 7-2, API 5DP, GOST and NS-1 standards. Production process involves forging, heat treatment, machining and others. Available sizes cover not only full ranges listed on standards but also BPE double shoulder connections and other types of premium connections, such as PAC, AOH, H90, Etc.

Fine die forging facilities

Size range: cover full tool joint specifications for 2 inch-7-5/8 inch drill pipe.

Features and benefits:

Forging with fine die forging facilities can ensure accurate shape of blanks, make a reasonable and uniform metal linear distribution, improve horizontal and longitudinal impact value, and enhance fatigue resistance.

Sophisticated manufacturing facilities are the basis of quality guarantees. BPE owns automatic continuous heat treatment furnace imported from Japan, which could ensure uniform and stable product performance of tool joint blanks by heating with natural gas. In terms of machining, BPE imports Japanese high accuracy CNC lathes, which could automatically control the threading precision.

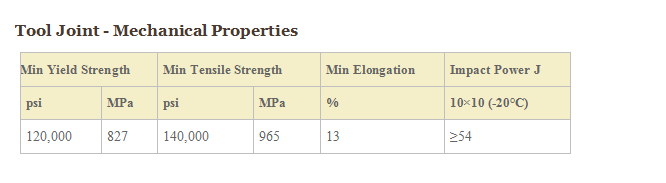

BPE strictly enforces standards of the API 7-2, 5DP, GOST, NS-1 during the entire production processes from initial materials selection, through forging, heat treatment, machining, magnetic particle and ultrasonic testing, cold rolling, surface treatment processes to final inspection. Production is with high yield strength, high impact value and long lifespan.