Products Categories

- Sand Control Pipes

- Casing & Tubing

- API Stabilizer

- DP & Hwdp& Drill Collar

- Top Drive Syetem

- Drill Rig Spare Parts

CONTACT US

- Add:binhai new district, tianjin city, china

- Tel:0086-22-25927368

- Fax:0086-22-25927369

- E-mail:471656480@qq.com

Your position:Product Categories > Drill Rig Spare Parts > Titanium Copper Clad Round Bar Ti- Cu Clad Flat Bar Anode

INTRODUCTION:

A. With advanced explosion-rolling process, we provide the first rate non-ferrous metal composites, mainly titanium clad copper and also including zirconium clad copper, 316L steel clad copper, titanium clad 316L steel plates, bars, tubes, composite wire, and multilayer clad composites, etc. The clad metal products could be up to four individual layers of metal or alloys. At minimum, there is a core and an outer layer, each layer thickness could be optimized to your needs.B. Processed products of non-ferrous metal, mainly titanium fasteners, screws, nuts, flanges and bends;

C. Titanium and titanium alloy bars, rods, tubes, pipes, plates, sheets, wires, coils, foils, and sections with high machining precision;

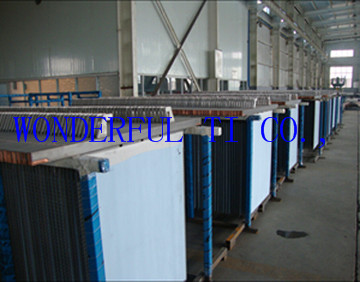

D. Various kinds of equipment made of titanium, such as titanium heat exchanger, titanium tray, and titanium anodes.

Titanium clad copper bars and other non-ferrous metals clad composite materials.

Titanium clad copper bars have been made by that a copper bar is clad in a certain thickness of titanium level, it mainly uses as a conductor under more corrosive work conditions. It is often used as a stand in plating, electrolysis, hydrometallurgy processes, because it has not only the original conductive property of the copper bar, but also protecting the copper bar from corrode by titanium level, and can greatly lower pollution of electrolyte and electroplate.

But, if you request that the material has this function above, then you must be sure that there are much stronger combination strength and much higher pasting rate between the copper bars and the titanium level, this can not be met by traditional mechanical combination methods. So in order to overcome it, our company, with advanced explosion-rolling process, has successfully produced titanium clad copper bars with sheared strength ≥ 130 Mpa, compact rate ≥ 98%, we can also supply the various specification of round, square, flat bars material, the longest length of the bars can reach above 10 meters and we can weld different shape material together in according to the clients request. We could also make nickel clad bars, stainless steel clad copper bars, zirconium clad copper bars series products through the same process technology.

Properties for Titanium Clad Composites

(1) Shear strength: The shear strength is tested and guaranteed in accordance with GB, ASTM, and JIS.

(2) Tensile strength: The tensile strength is guaranteed.

(3) Ductility: Ductility of cladding metal is guaranteed in face bend (=cladding metal in tension), and the ductility of base metal is guaranteed in reverse bend (=cladding metal in compression).

(4) Elongation: The lower limit of the elongation of cladding or base metal is guaranteed.

(5) Hardness: The bonded interface is slightly hardened after explosion bonding.

The interface can be softened by heat treatment to an original level.

There exists no difficulty in bending and drawing works.

(6) Corrosion Resistance: Explosion bonding, a clad processing, guarantees excellent corrosion resistance of clad materials.

(7) High reliability; High conductivity; Biocompatibility; Weld ability; Cost effective.

Wonderful group titanium and titanium alloy clad composites is the leader in the titanium industry. If you know the type clad composites you are interested in, you are kind to select it. When you are not sure which one you need, or would like to know more information, feel free to call us directly to discuss your particular requirement and we can help you decide which one is the best one.