Products Categories

- Sand Control Pipes

- Casing & Tubing

- API Stabilizer

- DP & Hwdp& Drill Collar

- Top Drive Syetem

- Drill Rig Spare Parts

CONTACT US

- Add:binhai new district, tianjin city, china

- Tel:0086-22-25927368

- Fax:0086-22-25927369

- E-mail:471656480@qq.com

INTRODUCTION:

Your BEST PROFESSIONAL TOP DRIVE SYSTEM SERVICE PARTNERwe could provide all the brand-new original TDS, such as VARCO, TESCO, CANRIG and MH.

With15 years' professional development, BPE has a team with more than 120 top drive engineers and cultivated at least 500 top drive employees, and could provide the TDS repair, on-site operation & maintenance, technical training and TDS spare parts.

Now we become the leader of top drive system service in china. Every year, our engineers provide service and maintenance for over hundreds of top drive for Varco, Canrig, Tesco, MH, BPM and so on in more than 20 countries.

BPE value is to keep your TDS in best condition and lower the operation risk.

BPE advantages:

·Over 15 years technology and experience accumulations in top drive system

·Total solutions in use and management for Varco, Canrig, Tesco, BPM and so on.

·Technology engineers with different professional technical background, training and service experience.

·On top of electronic control technology in Siemens, ABB, AB and YASKAWA, hardware configuration, software design, system debugging and troubleshooting.

·Expert team in machinery, electric and hydraulic to study new solutions and provide technology support for projects all over the world.

·Focus on technology development and innovation with many research results and patents for invention.

Technology Support

·API system and HSE system to enhance quality and safety management of projects, promote customer satisfaction by continuous improvement from system check and correction.

·Series of technical specifications including service regulations, service manual and all standard processed to normalize work standard and clear work process.

·Engineer training system and Star-engineer evaluation system to guarantee dispatching and capacity improvement.

·Cooperation with colleges and scientific research institutions to improve capacity of technology breakthrough and innovation.

·5 bases all over the world to provide top drive service in factory, technology support and material support.

·2 purchasing logistics centers in China and USA and multi storage centers all over the world into the whole Cruiser material supply network to satisfy project requirements in convenient and efficient way.

·Market centers in America, Mid-east and Southeast Asia to acknowledge customer needs all round and work out solutions.

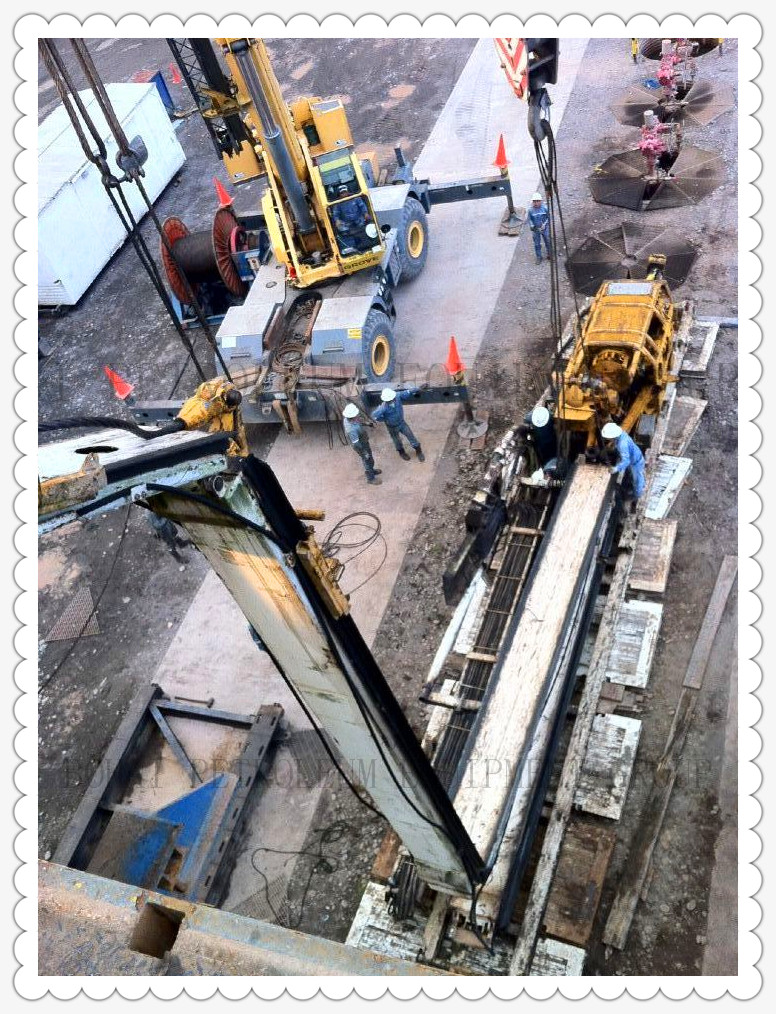

? The TDS service on-site

Advantages

· Professional Management System and Technical Team with Over 15 Years' Experience in Top Drive Service

· Service Solutions in Variety of Brands and Models

· Timely Technical Service Worldwide

· Powerful Professional Technical Team

Model

· On-site Service in Operation and Maintenance

· Suggestions in Model Selection

· Assistance in Equipment Acceptance

· Debugging and Daily Operation Maintenance of Top Drive

· Guide in Installation, Dismounting, Moving and Transportation of Top Drive

· Top Drive Operation Training

· Top Drive Troubleshooting

· Suggestions in Spare Parts Storage

· Preparation of Top Drive Operation Statement

Supervise Service in Operation and Maintenance

· Suggestions in Model Selection

· Assistance in Equipment Acceptance

· Top Drive Troubleshooting Daily Operation Maintenance

· Top Drive Troubleshooting Installation and Debugging

· Training in Top Drive Operation

· Top Drive Troubleshooting On-site

· Suggestions in Spare Parts Storage

· Equipment Regular Checkup

? The TDS repair on-site/ workshop

Advantages

· Maintenance Experience with over 100 Top Drive in Different Brands and Models

·Professional Technical Team

·5 Service Workshops in Asia, Europe and America

·Professional Service Tools and Testing System

Model

·Overhaul in workshop

· On-site Repair

· Regular Maintenance

? The original TDS spare parts

BPE also provides the original spare parts of VARCO, TESCO and CANRIG.

Product Description

New Varco Top Drive 500 tons rated at 7500psi Electric Model TDS-11SA with VFD Pkg complete, comes with pipe handlers model pH-75, motor housing, on board hydraulic power unit, roller style carriage, bail, integral swivel with goose neck and 7500 psi "S-Pipe" assembly, and a shipping storage skid, drilling fluids path pressure is 7500 psi. The unit comes equipped with a 7500 psi wash pipe assembly, rotary hose rating, two forced air cooled 400HP AC drilling motors (800HP total) a 10.5: 1 double reduction helical, quiet gear drive, hydraulic disk brakes, powered rotating head, counter balance and stand jump. Ready for deployment to rig site when delivered.

The AC drilling motors

The TDS-11SA uses two 400 or two 350 HP AC motors mounted vertically side by side on top of the main body to power the TDS-11SA.

The modified D-face attaches the drilling motors to the main body. This mounting method allows installation of the drilling motors without shimming or special alignment. Each motor has a double ended shaft with a drive pinion mounted on the lower end and a disc brake rotor mounted on the upper end. Two hydraulic caliper disc brakes, mounted to the top end of each motor, hold torque in the drill string and assist in positioning during directional work. An electrical solenoid valve remotely operates the hydraulic caliper disc brakes.

The AC drilling motors are an open-frame type, meaning that the cooing air passes through the inside of the motor. The drilling motors, manufactured specifically for top drive applications, have internal temperature sensors, vacuum varnish impregnated windings, high capacity bearing, and tapered output shafts to improve serviceability of the pinion gear and brake hubs.

The motor cooling system on the TDS-11SA is a local intake pressure blower type. It consists of two 5 HP AC motors integrally mounted on top of each AC drilling motor. Air is drawn in from the combination brake cover/air intake and delivered through rigid ducting to an opening in the top of each motor. The cooling air then passes through the inside of the open-frame type AC drilling motors and exits out of louver opening near the bottom of the motors.

TDS is one of the greatest technological revolutions of petroleum equipment which is used to replace Kelly and rotary table. TDS can drill with triples instead of singles which can reduce two-thirds volume of work of makeup and breakout and greatly increase drilling speed. The advantages of TDS is that in tripping if meets block up or struck, you can rotate the drill string while circulating mud flow so it can reduce drilling accidents. TDS can increase the level of mechanization of operation together with the wellhead system which can reduce the worker's labor intensity and the amount of operators. Especially in the directional well and cluster well, TDS has more advantages.

Specifications

Provide various brands of top drive for rental, e. G. Varco, Canrig, TESCO, BPM

Our Top Drive Rental Advantages:

1. Four stations can provide the quickest mobilization to the destination as customer's request.

2. Owning various world well known brands of top drive, (Manufacturer: Varco, Canrig, Tesco, BPM; Model: Electric or Hydraulic; Load: 250T/500T/750T); This can meet different customer's requirement in various environment.

3. A professional and experienced top drive service team.

4. A complete spare parts supply system.

Top Drive Rental Procedures:

1. Suitable top drive will be recommended according to customer's requirement (drilling rig's details and request for top drive)

2. Sign a top drive rental contract by negotiation.

3. Mobilization

4. Installation on site

5. Top drive working

6. Demobilization

7. Station restoration

Rental Mode:

1. Top drive rental + technical service

2. Top drive rental + technical service + spare parts supply

Top Drive Repair Content:

Top Drive Repair/ top drive Maintenance Service/ top drive spare parts

Top drive part repair, medium size repair and overhaul, repair in workshop or at oversea stations.

Top Drive Repair Procedures:

1. Confirm repair project

2. Making a repair outline or scheme

3. Sign the contract

4. Handing over the equipments

5. Top drive arriving in workshop or stations, and then disassembling

6. Top drive parts inspection

7. Top drive assembly

8. Top drive commissioning and leaving the workshop or stations

9. Customer acceptance

10. Installation and commissioning on site

11. Project completion reporting

Characteristics:

Drilling tools can be hoist at any time and well bore can be cleaned during drilling to reduce accidents. In tripping if meets block up, you can connect the drill string quickly and circulate mud and make back reaming so that it can reduce sticking accidents.

Integrated with mechanic, electric and hydraulic control system. The AC output parameters of frequency converter match with the performance requirement of motor. The self-designed PLC program is simplified which can be designed according to the requirement of customer. It has the function of protection and interlock, which is more suitable to the drilling condition.

The rotating head has two oil channels to supply oil to the tilt hydro cylinder to realize the forth tilt and back swing of link. Each oil channel is with dual seal for oil leaking accident reduced greatly and improving the reliability of system. When tripping operation, rotating head can rotate with drilling tools and it is easy to handle drilling accidents.

Adopt the plug-in type housing structure, the back-up tong and IBOP hydro cylinder don't rotate with the rotating head and the structure is simple.

Adopt double load path: When drilling operation, the bearing of gearbox bears the load. When tripping operation, the bearing of rotating head bears the load. It can greatly increase the service life of bearing and main shaft.

BOHAI petroleum equipment group co., limited ( hereinafter referred to BPE) is the professional global petroleum drilling equipment manufacturer with the Chinese petroleum industrial development. Based on Dagang oilfield found in 1964, BPE has provided not only reliable API drilling equipment, but also high-quality top drive system repair services to CNPC, Sinopec, CNOOC, CPTDC, and exported our high quality drilling equipment and service to more than 30 counties in Africa, middle-east, America, Asia.

One-stop drilling equipment supplier saves your time and energy

With our business and technical development trend, we have divided our group into six business divisions:

The sand control screen division

Its main sand control screen pipes includes: High quality slotted liner for oil and water well , new designed keystone slotted liner, advanced perforated pipe, reliable rod-based wire wrapped screen, durable pipe-based wire wrapped screen, pre-packed screen, and bridge slot screen,

The casing and tubing division

Its main products: API casing pipe, API tubing, casing coupling, tubing coupling, casing thread protector, tubing thread protector, casing pup joint, tubing pup joint, high temperature and pressure thread sealing grease.

The stabilizer division

We could produce all kinds of API and NON-API stabilizer: Integral Spiral Blade Stabilizer, Integral Straight Blade Stabilizer, Replaceable Sleeve Stabilizer, Tapered Stabilizer, Float valve stabilizer, Welded Blade Stabilizer, Non-Rotating Stabilizer, Roller Reamer

The drill pipe division

We could produce API drill pipes, heavy weight drill pipes, drill collar, Kelly.

The top drive system division

The top drive system has more advantages than the rotary table, and it is used in more and more drilling rigs due to its safer, higher drilling speed and efficient. We could provide the rapid and timely TDS repair and maintenance service, but also the VARCO, CANRIG, TESCO, MH and BPMC TDS original spare parts.

The drilling rig accessories and spare parts division

Sucker rod coupling, hose, float shoe, float collar, liner hanger, and so on.

Our consistent stable quality enhances your drilling safety and efficiency

Any minor quality defects maybe could lead to catastrophe during drilling. We produce every petroleum equipment strictly according to API standard, and also got other certificates, such as ISO9001, ASME, DNV, and GOST. We have professional quality department to conduct the quality inspection, train, evaluations. At the same time, we could provide SGS inspection to make you free.

Competitive price maximizes your profit and make you become a winner

Our large scale material purchase lower the average cost to make our drilling equipment price more competitive. Every division has its production line, and do not need to outsourcing, so not only decrease the processing cost, but also guarantee the quality. Our R &D team also focuses on ensuring a perfect match between product performance and customer demands to reduce the total cost with customized integration solutions.

Sound service system minimizes your risk and let you head free

100 after-sales engineers in our group are always striving to meet our customers' requirements. 7-24 hotlines could solve your any questions any time. We have long-term cooperation logistics partners and guarantee to delivery your goods safe and fast.

We are looking forward to cooperate with friends from various circles at home and abroad and to achieve the win-win situation for everyone involved, creating the petroleum drilling equipment more brilliant tomorrow together!

If you have any questions, please do not hesitate to contact me.

TEL: 0086-13516251207